- 5‑Thread Safety Stitch – Provides both overlock and chainstitch in one pass, ensuring strong, reinforced seams.

- High‑Speed Output – Up to 6,000 stitches per minute for efficient production.

- Direct Drive Motor (common in this class) – Energy‑saving, quieter, and more precise than clutch motors.

- Durable Construction – Handles medium to heavy fabrics such as denim, uniforms, and workwear.

- Basic Model – Unlike the EA‑7725E1 or EA‑7915D4, this version does not include pneumatic automation or advanced trimming systems, making it simpler and more cost‑effective

-

The EA‑7725E is a high‑speed, industrial 5‑thread basic overlock machine designed for durable garment finishing. It combines a 3‑thread overlock with a 2‑thread chainstitch (safety stitch), runs up to 6,000 stitches per minute, and is built for medium to heavy fabrics. Key Features

The EA‑7725E is a high‑speed, industrial 5‑thread basic overlock machine designed for durable garment finishing. It combines a 3‑thread overlock with a 2‑thread chainstitch (safety stitch), runs up to 6,000 stitches per minute, and is built for medium to heavy fabrics. Key Features -

The EA‑7724E is a high‑speed, industrial 4‑thread basic overlock machine designed for professional garment finishing on light to medium fabrics. It runs up to 6,000 stitches per minute and provides strong, flexible seams without the added automation of thread trimming or pneumatics. Key Features

The EA‑7724E is a high‑speed, industrial 4‑thread basic overlock machine designed for professional garment finishing on light to medium fabrics. It runs up to 6,000 stitches per minute and provides strong, flexible seams without the added automation of thread trimming or pneumatics. Key Features- 4‑Thread Overlock – Produces durable, stretchable seams with a neat edge finish.

- High‑Speed Output – Up to 6,000 stitches per minute, making it suitable for mass production.

- Direct Drive Motor (typical setup) – Energy‑efficient, quieter, and more precise than clutch motors.

- Basic Model – Unlike the EA‑7724E1 or EA‑7914D4, this version does not include thread trimming or pneumatic automation, keeping it simple and cost‑effective.

- Durable Build – Designed for continuous industrial use.

-

The EA‑7723E is a high‑speed, industrial 3‑thread basic overlock machine designed for clean edge finishing on light to medium fabrics. It runs up to 6,000 stitches per minute and is the simplest model in Eastman’s 7700 series, making it reliable, cost‑effective, and easy to maintain. Key Features

The EA‑7723E is a high‑speed, industrial 3‑thread basic overlock machine designed for clean edge finishing on light to medium fabrics. It runs up to 6,000 stitches per minute and is the simplest model in Eastman’s 7700 series, making it reliable, cost‑effective, and easy to maintain. Key Features- 3‑Thread Overlock – Produces neat, narrow seams and edge finishes, ideal for preventing fraying.

- High‑Speed Output – Up to 6,000 stitches per minute for efficient production.

- Direct Drive Motor (typical setup) – Energy‑saving, quieter, and more precise than clutch motors.

- Basic Model – No thread trimmer or pneumatic automation, keeping it simple and affordable.

- Durable Build – Designed for continuous industrial use with minimal maintenance.

-

The EA‑0611D is an industrial needle feed walking foot machine designed for heavy‑weight fabrics, equipped with an automatic thread trimmer and direct drive motor for precision and efficiency. Comes with an automatic thread trimmer. Suitable for Heavyweight fabrics.

The EA‑0611D is an industrial needle feed walking foot machine designed for heavy‑weight fabrics, equipped with an automatic thread trimmer and direct drive motor for precision and efficiency. Comes with an automatic thread trimmer. Suitable for Heavyweight fabrics.- Needle Length: 38mm

- Distance between stitches: 9mm

- Presser foot lift: 8/16

- Stitches per minute: 2200

-

EA-8957CE4 - Drop Feed Lockstitch Machine Comes with automatic thread trimmer and automatic foot lift. Suitable for Medium-weight fabrics for general or plain operations, low noise level and low vibration.

EA-8957CE4 - Drop Feed Lockstitch Machine Comes with automatic thread trimmer and automatic foot lift. Suitable for Medium-weight fabrics for general or plain operations, low noise level and low vibration.- Needle length: 30.7mm

- Distance between stitches: 5mm

- Presser foot lift: 5.5/13

- Stitches per minute: 5000

-

EA-9310E4 - Needle Feed Lockstitch Machine Comes with automatic thread trimmer, integrated semi-oil lubrication and automatic foot lift. Suitable for Medium-weight fabrics for general or plain operations, low noise level and low vibration.

EA-9310E4 - Needle Feed Lockstitch Machine Comes with automatic thread trimmer, integrated semi-oil lubrication and automatic foot lift. Suitable for Medium-weight fabrics for general or plain operations, low noise level and low vibration.- Needle length: 33mm

- Distance between stitches: 4.5mm

- Presser foot lift: 5.5/13

- Stiches per minute: 5000

-

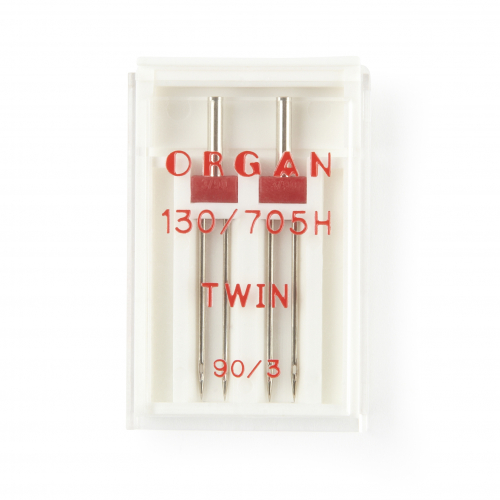

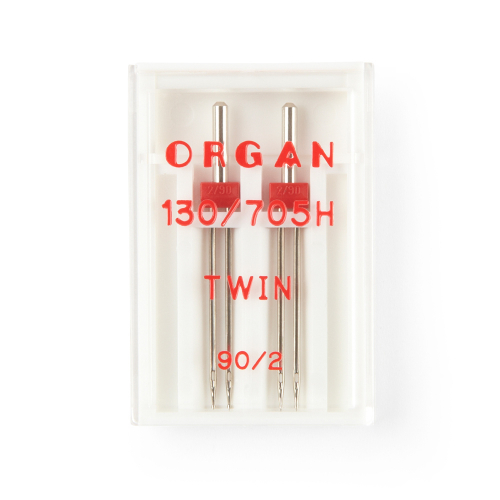

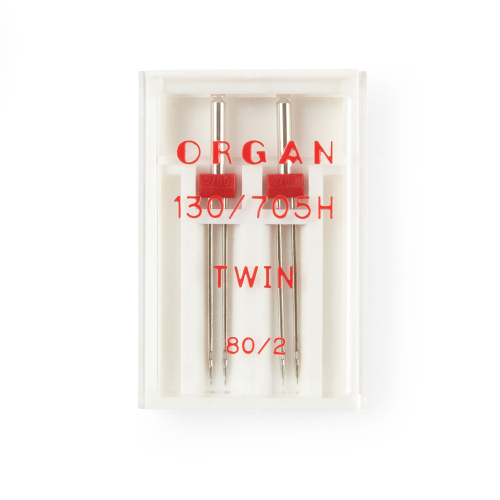

130-Multi Assorted Multibox Needles

Organ has put together this multi-pack that contains the following The pack contains: 1 x 80/2 Twin Needle, 1 x Universal 80, 1 x Universal 90, 1 x Jeans 90 and 1 x Stretch 75 - Sewing Machine Needles Twin needles are attached to the one shank so that you can sew two perfectly parallel rows of stitching at the same time.